X and Z directions are the same, but arcs go the wrong way. Swapped G2 and G3 because solidcam works above the part, and mach3 below the part. Included missing spindle speed in a G98/G97 line, which made mach3 protest.Īdjusted the startup and end coordinates to fit within my relatively small (14") lathes working area.

Removed the program number with colons which made mach3 protest. I have done the following modifications to make it work with Mach3: I sat down to make it work with my Mach3 lathe and Solidcam2015, studied the Gcode, and found what needed to bed fixed. I don't remember exactly where i downloaded it. Drive Unit Sharing: two tools working simultaneously while single Drive Unit (spindle) rotates with the same RPM's and direction.Included is a Modified FANUC2013 Turn postprocessor for SolidCam, posted by some kind person on this forum.

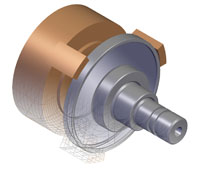

4th Axis Simultaneous Turning: performs machining of curved profile, using B-axis tilting capabilities of the tool, in order to machine undercut areas in a single step.HDT & FreeTurn cuts your machining time by up to 25%. All familiar turning operations such as roughing, finishing, contour turning, facing and longitudinal turning can now be completed using just one tool.

0 kommentar(er)

0 kommentar(er)